If your business functions with manufacturing or processing systems that need an extremely precise application of heat, you may have considered investing in the best cartridge heater manufacturer.

In this post, we will discuss all the significant things that you must know when looking for the best heater manufacturer for your industrial or commercial uses.

What is a Cartridge Heater?

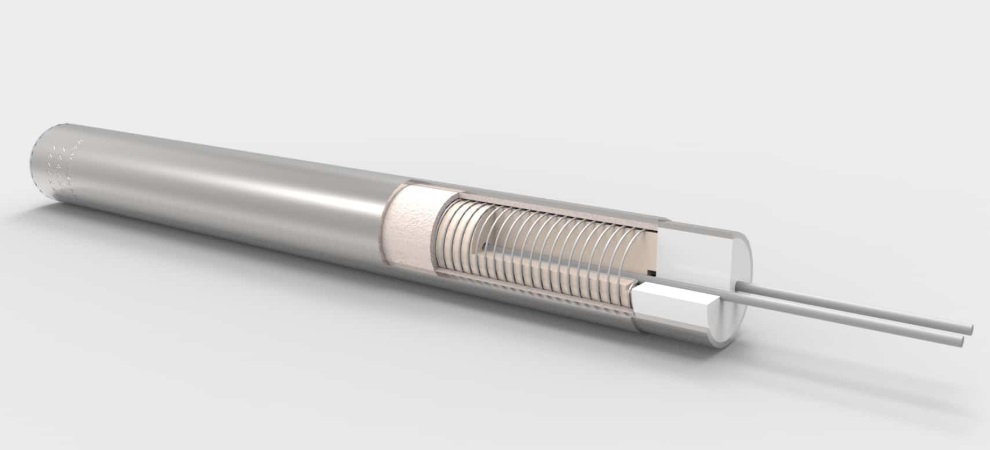

A cartridge heater involves a cylindrical tube-type structure with a metal cover containing a resistive electrical circuit covered inside with effective insulation. It is a heating attribute employed in different industrial applications. This kind of heater is made in such a manner that the diameter has a definitive dimension that can drift into holes of metric drill sizes, generally varying from 4mm to 20mm. The length might differ from less than an inch to some feet. Normally, these heaters are employed to heat solids by conduction. The heater is manufactured to slip into the hole and be accomplished into a mold, including the solid. Consistent heating is a worthwhile feature of these heaters.

Essential Features That Make a Cartridge Heater Desirable

Some specific features of these heaters make them fascinating for different industrial purposes, such as:

1. These are made with internal thermocouples.

2. These are accessible with lead wire options.

3. Come with flanges and fittings.

4. Higher performance in the sense of consistency in heating.

5. Highly durable.

6. Come in various configurations and constructions according to particular application.

7. Conforms to global performance norms.

Various Industrial Applications of Cartridge Heaters

Various industrial and commercial units employ these heaters in their regular processes. At present, these devices are being utilised for the following activities in industries:

1. For packing.

2. Heating gases and liquids.

3. Plastic processing plants.

4. Labeling machineries.

5. Hot runner mold and hot stamping.

6. Dies and molds.

7. Food processing machines.

8. Shoe making machines.

Benefits a Cartridge Heater Offers

1. Accurate and Precise

One of the finest features of the cartridge heater is that these tools can be employed to apply heat in a minimal, focused, highly controllable and precise way. This allows the user to maintain precise quality control.

2. Come in a Number of Sizes

Whether you need heating equipment that is very compressed or somewhat larger, you will be able to find a cartridge heater to fulfil your needs.

This can be very useful when working within strict parameters and in restricted space. In addition, selecting a cartridge heater of the correct size and length can improve all of the other advantages of this device.

3. Best for Decreasing Condensation

One essential benefit of cartridge heaters is their capability to fight off the drawback of many heating equipment, which is condensation. It can negatively affect sensitive equipment and feasibly cause costly damage. These devices successfully reduce this issue by adjusting air temperature.

4. Minimum Loss of Energy

One more benefit of these heaters is that they are some of the most cost-effective choices in heat transfer. They lose very low energy, letting you keep overheads low. This effectiveness also lets your organisation decrease its environmental effects.

5. Overheating is Less Possible

Finally, the capabilities of these heaters make damage to equipment and products less feasible because of overheating. This signifies that heaters of this type need less tracking than other similar tools and low maintenance.

How to Select the Best Cartridge Heater Manufacturer?

Cartridge heaters are normally used in industrial procedures such as mold dyeing, sealing bars, platen heating and other processes. If you are searching for a heater that matches your needs, here are a few significant things that you must consider while choosing any cartridge heater manufacturer:

1. The quality of the material to be heated.

2. The material’s mass to be heated.

3. The maximum watt density for the substance.

4. The primary temperature.

5. The final temperature to be obtained.

6. Target time in which final temperature is to be obtained.

7. Accessible phase and voltage.

Once these fundamental parameters are considered, the heater type, size, rating and quantity can be chosen. The number of heaters needed must be determined so as to give consistent heating to the material. For precise temperature control and constant heating, the sensor must be kept close to the working region. As the wattage for the heater is decided, the heater dimensions and wattage density are to be chosen. In some conditions, the wattage density goes above the acceptable value. In these cases, the measurements, number of heaters, and loss of heat are to be adjusted.

Final Words

Cartridge heaters manufactured with customised specifications and features are used for particular applications. From composition to lead angle, every attribute of these heaters is personalisable, making them the most desirable device in different industries.

Marathon Heat India Private Limited is a Cartridge Heater manufacturer that offers unique features to provide effective heat transfer at a very consistent and standard temperature.